On-Site Machining

On-Site Machining

SEAFIRST MARINE LIMITED has built up a very professional and experienced team which specializes in all kinds of in-situ machining. These equipments are designed by our own company and are one of the most efficient tools on for ship repair.

In-situ milling for flange surface

Our engineers can carry out in-situ milling for flange surface of deck cranes and other equipments. The machining is needed especially after new flange is welded to the pedestal or if there is any deformation on these flange surfaces. The work range can be up to 5 meters diameter and our equipment can be disassembled into small parts so it is easy to transfer for various jobs at different ports.

Machining Range: Φ 1250mm-5000mm

Installation of the equipment before machining Flange surface after machining

In-situ machining for shafts

Our self-designed on-site machining equipments are provided for various crank shafts/pins of engines/generators, shafts of cranes etc. By our equipments and advanced electronic/laser measuring instruments, top quality with split-second precision can be obtained.

Machining sizes:

Shaft size:Φ 150mm-850mm

Cylindnicity:0.01mm

Parallelism:0.02mm

Surface Roughness: Ra0.4

Shaft machining equipment After machining

In-situ machining for holes

We can offer top quality machining for axis hole, rudder blade hole and hole of main shaft of generator etc. All these machining equipments are self-designed and can be adjusted according to the on-site conditions, which make them be able to run different jobs under different conditions.

Machining size:

Hole size: Φ 60mm-900mm

Cylindnicity:0.01mm

Surface Roughness: Ra0.4

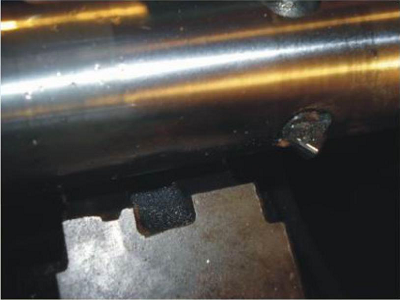

Install equipment for two holes machining Machining tips by our equipment

Machining taper hole on rudder blade Taper hole machining tool

In situ horning for cylinder liner

Our engineers are skillful and experienced on horning for cylinder liners. Our horning equipments are provided for engine frames, cylinder, cylinder cover etc.

Machining sizes: Φ 260mm-1200mm

In-situ drilling holes

The imported equipment from German makes it easy to drill holes for different purpose.

Drilling size:

Hole size: Φ 12mm-120mm

Depth: 110mm

Equipment installation for hole drilling Drilling hole on the bolts