Turbocharger Maintenance & Repair

Turbocharger Maintenance & Repair

TURBO CHARGER REPAIR

Rather than incur the expense of purchasing a brand new turbocharger for your engine, you may want to consider having us repair or rebuild your turbocharger. With more than 6 years of experience in ship, aircraft and diesel turbochargers, we provide competent repair and service expertise with the latest equipment.

Echoing our commitment to quality, our facility has been certified to the highest of standards in the industry. Our turbochargers repair and rebuild service is a quick and high quality service. All turbochargers are cleaned, inspected and rebuilt to OEM specification.

Mainly engaging in:

Maintaining multifarious models of turbochargers, such asMET,MAN,ABB, NAPIER,H.S.M,SULZER series etc.

a. Repairing and reblading of Turbine blade

b. Chemical cleaning and recondition of silencer

c. Dynamic balancing test, such as types of fan blade, the oxygen generator rotor,chemical rotor, the motor rotor

d. Flying blast of turbine blades

e. Flying blast of nozzle ring and cover ring

f. Dye penetration of turbine blades, compressor wheels and nozzle ring blades

g. Spraying ,painting as well as welding of rotor shaft to specification

Supplying and processing spare parts for Turbocharger

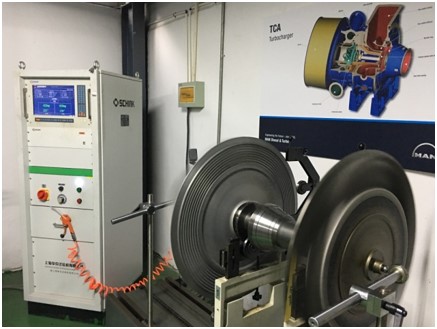

Major equipments for turbocharger maintenance:

a. Balancing Machine/ Schenck Germany(H40BU/ 1set;YYQ50/ 1set)

b. Governor test bed

c. Electric welding, gas welding equipment, thermal spray equipment

d. Desktop drill, C6250 lathe, milling machine

e. Water blasting machine (S50C 1-Taiwan), fly blasting equipment

f. Welding equipment (Panasonic), dying testing equipment

g. Precision grinding equipments

h. Advanced measuring devices: hardness tester, ultrasonic thickness instruments, infrared thermometer and seismic instrument etc.